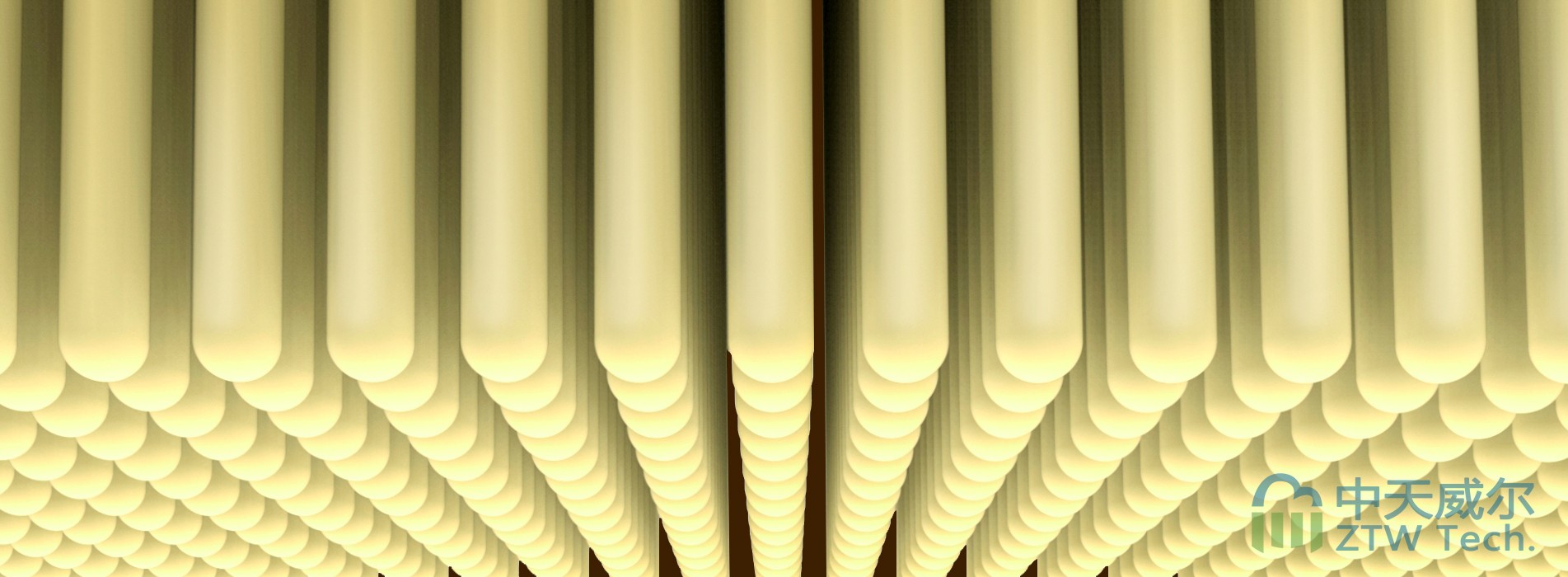

Robust Emission Control Systems: ZTW Tech's Ceramic Integration Solutions for Multi-Pollutant Ultra-Low Emissions

Robust Emission Control Systems: The Ceramic Integration Revolution for Industrial Kilns In today's stringent regulatory landscape, industries operating glass furnaces, biomass boilers, waste incinerators, steel sintering lines, and high-fluorine processes face mounting pressure to achieve and maintain ultra-low emission standards. Traditional sequential treatment trains—combining Selective Catalytic Reduction (SCR), baghouses, electrostatic precipitators, and dry scrubbers—often struggle […]